TECHSPECS

| Product Family | CounterM.A.T.E. Jr. | CounterM.A.T.E. X | CounterM.A.T.E. Pro |

|---|---|---|---|

| Motor Type | Induction Motor | Induction Motor | Permanent Magnet Motor (servo) |

| Power Requirements (Min.) | 120V single phase | 208V/480V 3-phase | 480V 3-phase |

| Performance Category | Entry-level | Medium | High |

| Quick Change Control Cabinet | ✓ | ✓ | ✓ |

| Absolute Encoders | ✓ | ✓ | ✓ |

| Individual Controller for Each Set | ✓ | ✓ | ✓ |

| Secondary Brakes | ✓ | ✓ | ✓ |

| Fits on 8" Centers | ✓ | ✓ | ✓ |

| Suitable for New Construction and Retrofit | ✓ | ✓ | ✓ |

| Re-use Existing Rigging (Subject to Inspection) | ✓ | ✓ | ✓ |

| Fully Captured Guide Chain | ✓ | ✓ | ✓ |

| Multiple Patents | ✓ | ✓ | Pending |

| Redundant Limits | ✓ | ✓ | ✓ |

| SIL-3 Compatible E-Stop | ✓ | ✓ | ✓ |

| Joystick Control | ✓ | ✓ | ✓ |

| ANSI/ESTA Code Compliant | ✓ | ✓ | ✓ |

| Global Control Console | ✓ | ||

| Pendant Controller (Optional) | ✓ |

| Family | Model | Maximum Scenic Load | Max Speed (feet per minute) | Minimum power required | Great for |

|---|---|---|---|---|---|

| CounterMate Jr | JR-GP-750 | 750 lbs | 0-100 fpm | 120v 1ϕ | Typical scenic elements and soft goods |

| JR-EL-1250 | 1250 lbs | 0-20 fpm | 120v 1ϕ | Electric lighting battens | |

| JR-HD-2000 | 2000 lbs | 0-10 fpm | 120v 1ϕ | Moderately sized orchestra shell ceilings | |

| CounterMate X | X-GP-1200 | 1200 lbs | 120 fpm | 208v/480v 3ϕ | Balance of speed and capacity suitable for most PACs |

| X-EL-1750 | 1750 lbs | 0-20 fpm | 208v/480v 3ϕ | Larger electric lighting battens | |

| X-HD-3300 | 3300 lbs | 0-10 fpm | 208v/480v 3ϕ | Large orchestra shell ceilings | |

| CounterMate Pro | PRO-GP-1300 | 1300 lbs | 180 fpm | 480v 3ϕ | Ultra-fast scenic automation |

| PRO-GP-1800 | 1800 lbs | 120 fpm | 480v 3ϕ | Large, fast-moving scenic elements |

CAPACITIES

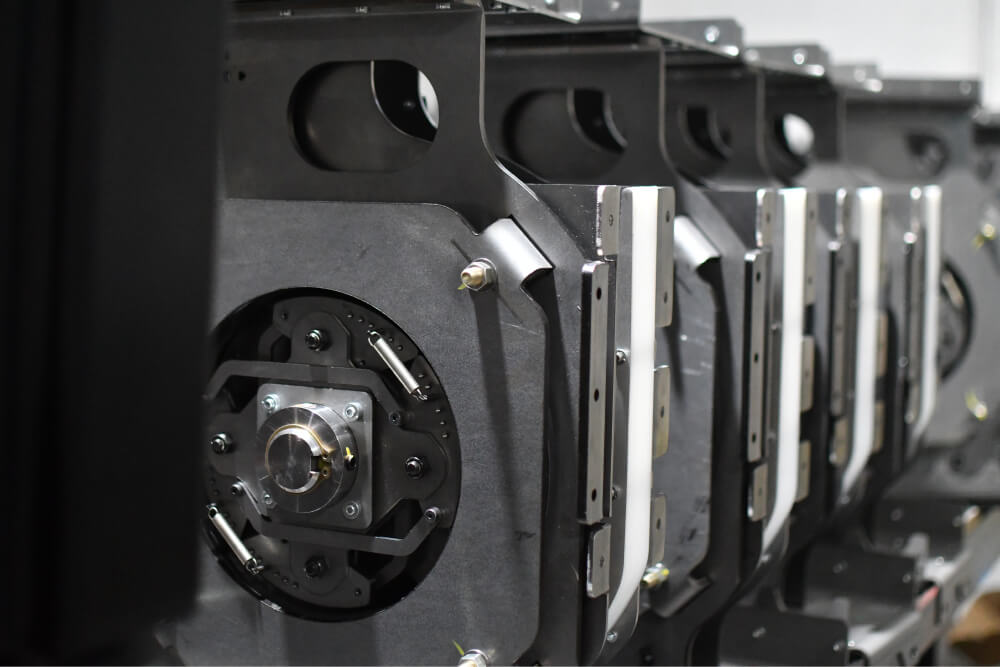

The arbors are sealed, meaning there is no need to handle or adjust counterweight. During installation and commissioning, the batten is balanced with counterweight. Then, 50% of the total set capacity is added to the arbor. The motor compensates for the difference using a fully captured drive chain and numerous industry-leading safety features. All listed capacities represent maximum scenic loads.

Safety featureS

- Absolute encoder provides extreme precision.

- Primary motor brake

- Secondary bi-directional centrifugal brake

- Software defined travel limits

- Redundant hard struck ultimate travel limits

- Data logging & storage

- Category 0 emergency stop

- Safe-torque off (“STO”)

- Onboard diagnostics (VFD, encoder, and other fault statuses)

- Inspection/service indicator

- Factor of safety exceeds 8:1 for all drive components

- Meets and/or exceeds all relevant standards including ANSI E1.6-1-2019 ESTA standard for Entertainment Technology – Powered Hoist Systems